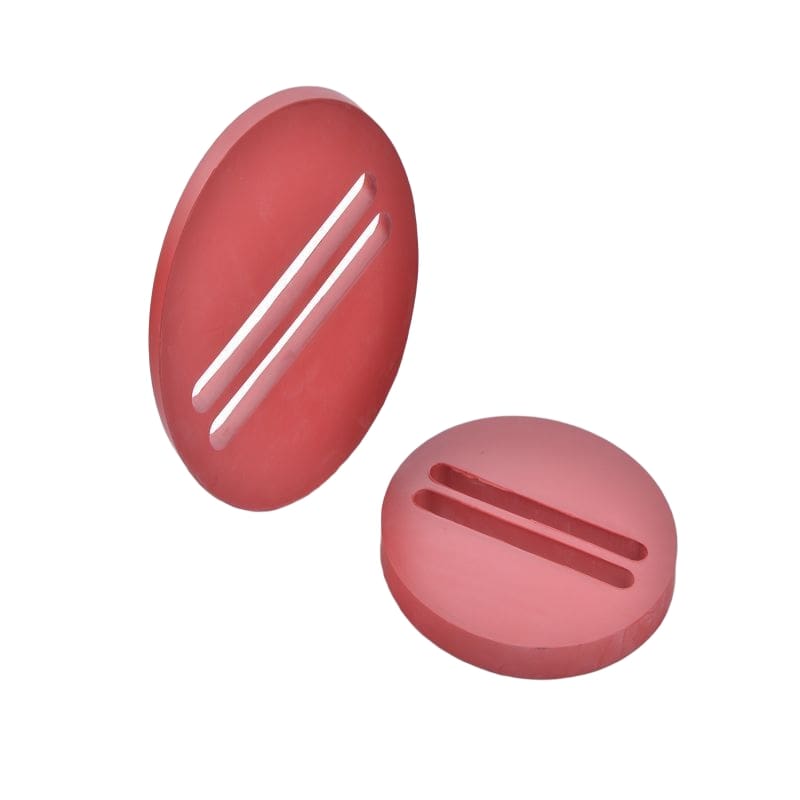

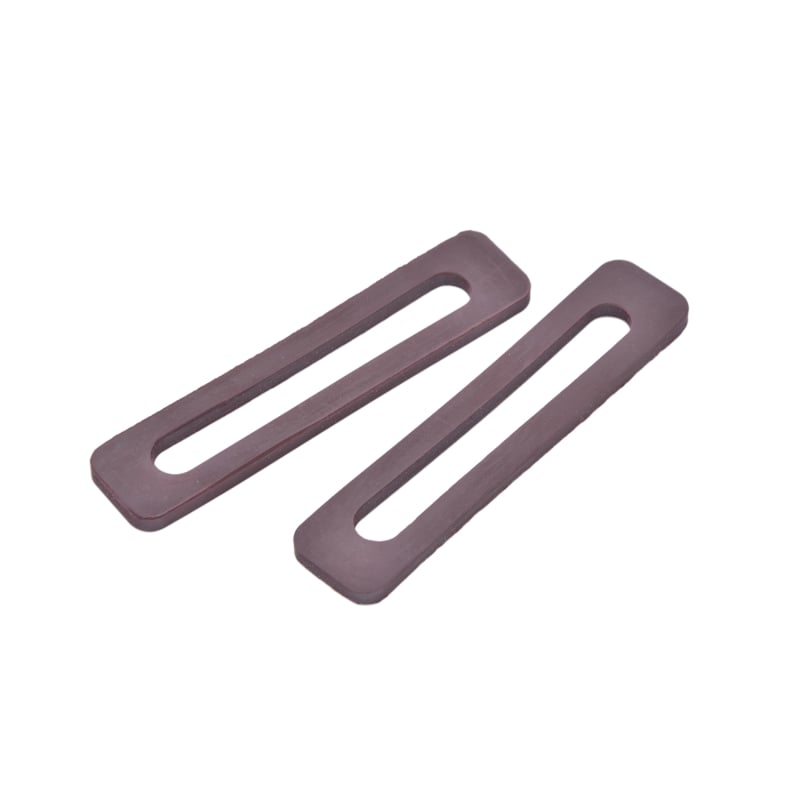

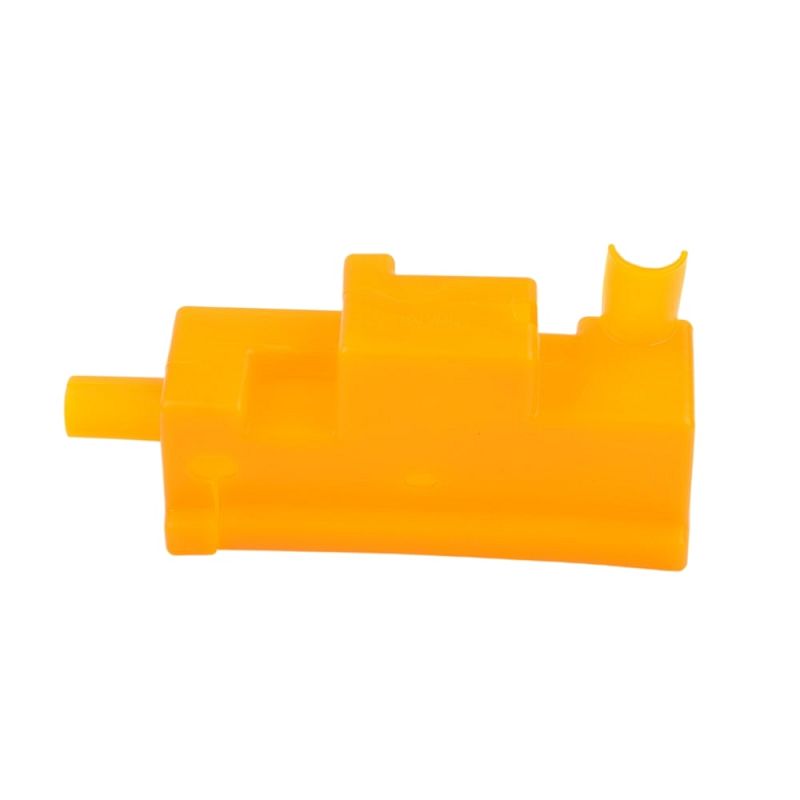

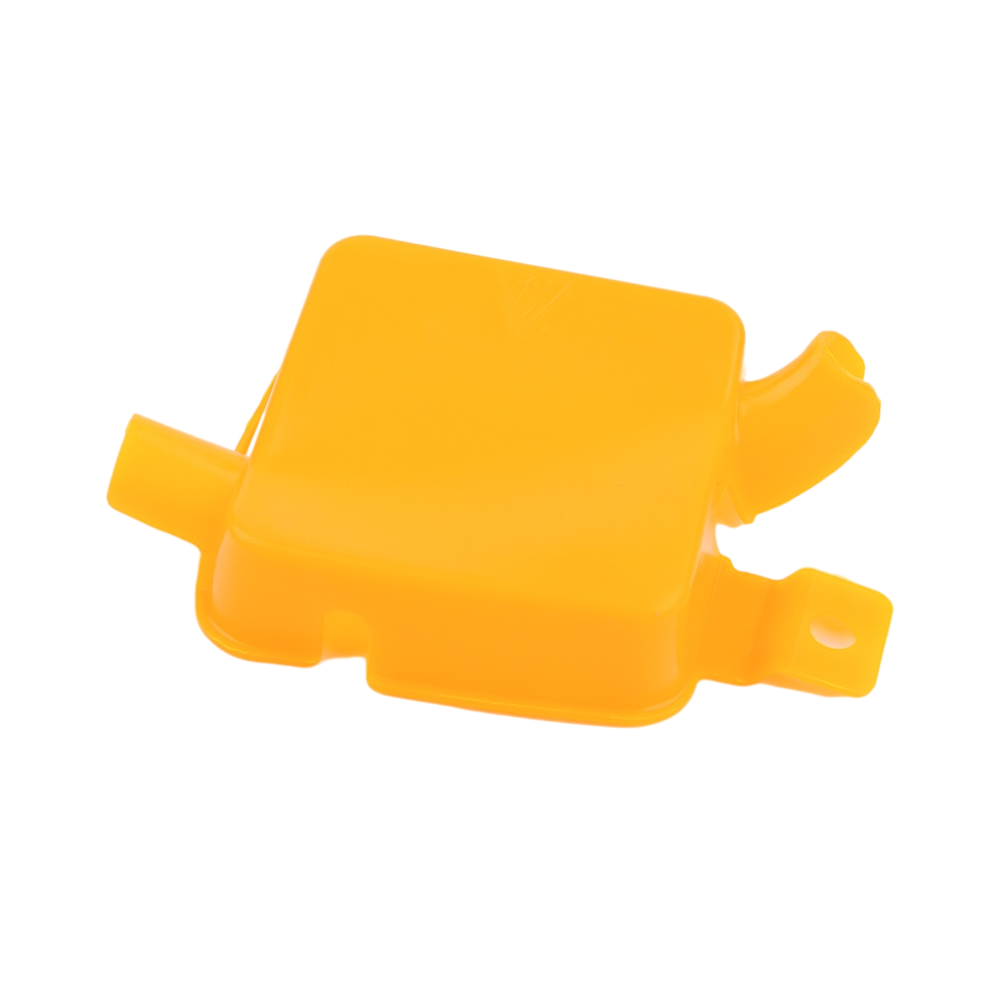

Industrial Silicone Rubber Bolt Cover & Wildlife Protective High Voltage Sleeve

Silicone Rubber Bolt Covers and High Voltage Insulator Sleeves. Engineered from advanced Liquid Silicone Rubber (LSR), these components are designed to provide superior insulation and protection for power distribution equipment.

Our bolt covers act as a critical shield in electrical substations and overhead lines, effectively preventing outages caused by accidental contact from wildlife (birds, squirrels) or harsh weather conditions. With excellent hydrophobicity and tracking resistance, they ensure long-term reliability without the need for frequent maintenance.

Key Features & Performance

Superior Insulation High dielectric strength prevents current leakage and flashovers in high-voltage environments.

Wildlife & Bird Protection Prevents short circuits caused by animals bridging the gap between phase-to-phase or phase-to-ground.

Weather & UV Resistance Excellent resistance to ozone, UV radiation, and extreme temperatures (-50°C to +200°C), ideal for outdoor use.

Easy Installation Flexible silicone material allows for quick installation on bolts, bushings, and terminators.

High Efficiency Production Manufactured using LSR injection molding for precise tolerances, no flash, and consistent quality.

Hydrophobic Surface Repels water and moisture, preventing the formation of conductive paths (tracking).

Common Applications

Our insulating covers are widely used in the electrical power industry for:

| Transformers | Protecting bushing connections and lightning arresters. |

|---|---|

| Switchgear & Substations | Insulating exposed busbars, drop-out fuses, and disconnect switches. |

| Overhead Distribution | Covering cable terminations, clamps, and dead-end insulators. |

| Surge Arresters | Protective caps for top terminals to prevent environmental corrosion. |

Technical Specifications

| Material Type | High Voltage Grade Liquid Silicone Rubber (LSR) |

|---|---|

| Color | Grey (Standard for Industry), Red, or Custom Pantone |

| Hardness | 40 - 70 Shore A (Adjustable per requirement) |

| Operating Temp | -50°C to +200°C |

| Dielectric Strength | ≥ 22 kV/mm |

| Volume Resistivity | ≥ 1.0 x 1014 Ω·cm |

| Flammability | UL94 V-0 / HB |

| Standards Compliance | RoHS, REACH, IEC 60815 (Reference) |

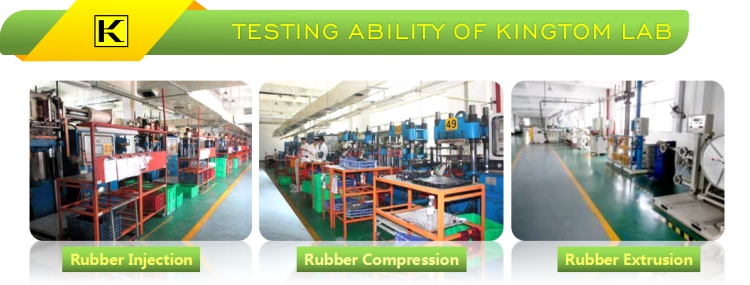

Kingtom In-house Laboratory for Quality Assurance

Frequently Asked Questions

What products does Kingtom specialize in?

We focus on Rubber Injection parts, Compression parts, Extrusion parts, and Rubber-to-Metal bonded parts for Automotive, Electrical, and Industrial applications.

What do I need to provide for a quote?

To provide an accurate price, please send us:

1. Drawings: 2D (PDF) or 3D (STEP/IGS).

2. Material Specs: Type of rubber and Hardness.

3. Quantity: Estimated order volume.

Can you produce without a drawing?

Yes. If you do not have a 3D drawing, please send us a physical sample. Our engineering team can reverse-engineer the part to create the mold data.

How do you control quality?

We are an experienced manufacturer with strict QC procedures. We provide First Article Inspection (FAI) reports for samples and detailed inspection reports with photos before mass production shipment.

Need a custom silicone solution?

Contact us today with your drawings or requirements.